Services

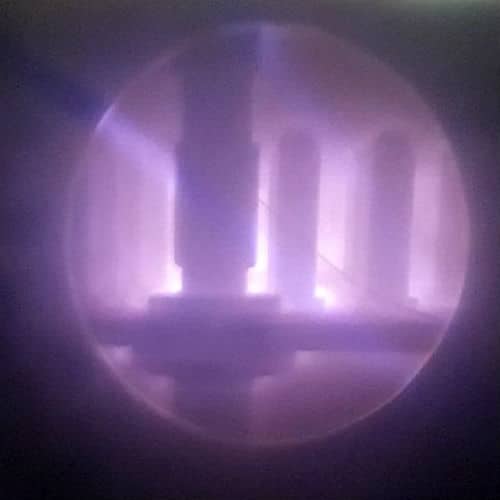

Since 1955, Hansen/Balk has built a reputation as a state-of-the-art provider of steel heat-treating services. Our 85,000-square-foot facility features a full cohort of best-in-class batch vacuum and batch atmosphere furnaces, capable of processing orders of all sizes.

We offer a variety of services, but are best known for the breadth and depth of our vacuum heat-treating capabilities—including high-pressure quenching up to 15 Bar—as well as unique services such as cryogenic treating, flame hardening and induction heat-treating services. We adhere to the most technologically advanced heat-treating methods with modern equipment to ensure your parts meet the required specifications—from hardness tolerance to surface finishes. We also bring customers a deep well of metallurgical knowledge, formed over six decades of work on millions of parts.

Hansen/Balk is Nadcap and MedAccred accredited and AS9100 registered. We also hold a number of customer approvals including ISO 9001, General Motors Powertrain Specification HPDC-G-2 and Ford Motor Company AMTD-DC2010.

Our services include:

- Vacuum Heat Treating

- High Pressure Quenching up to 15 Bar

- Vacuum Tempering

- Ion Nitriding

- Gas Nitriding

- High Speed Steel Heat Treating

- Stainless Steel Heat Treating

- Carburizing

- Cryogenic Treatment

- Flame Hardening

- Induction Heat Treating

- Stress Relieving

- Atmosphere Hardening

- Atmosphere Annealing

- Annealing

- Martempering

- Normalizing

- Precipitation Hardening

For more information about our services, contact us or request a quote.